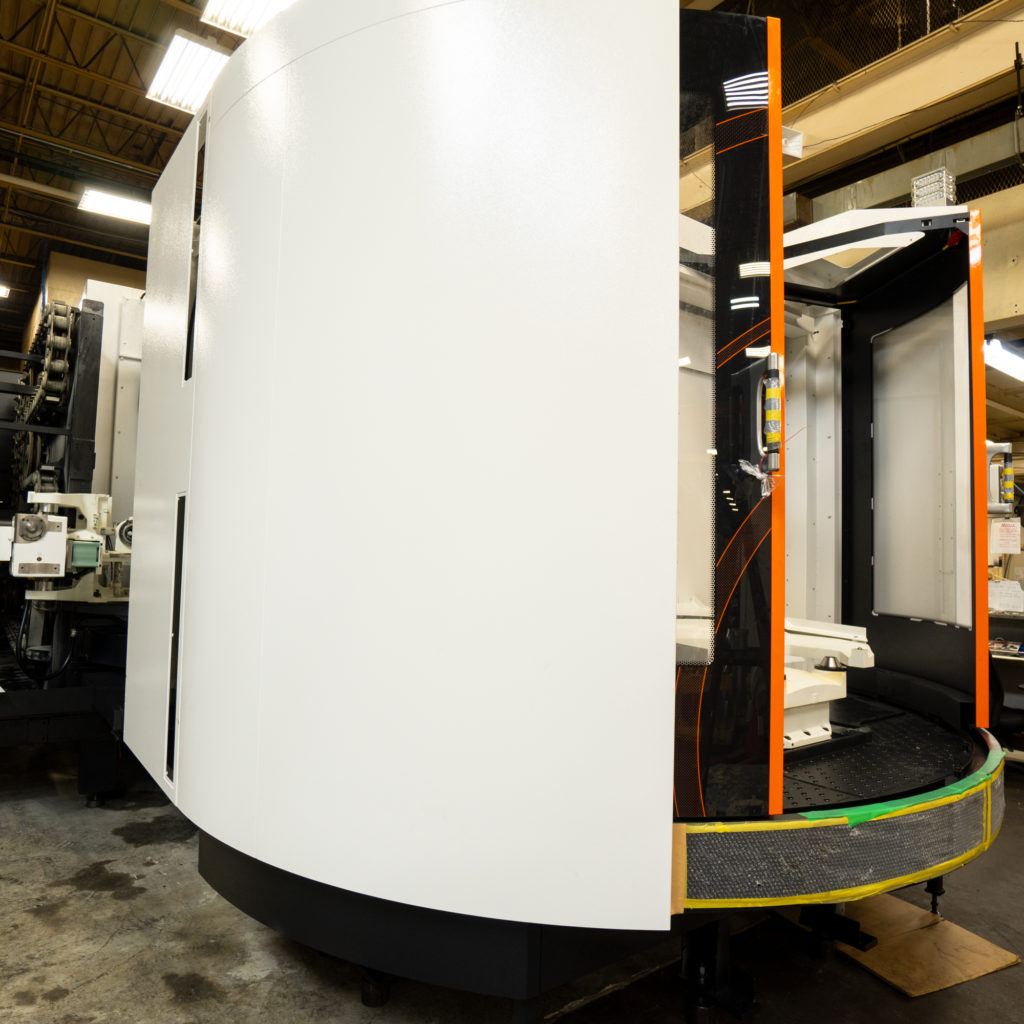

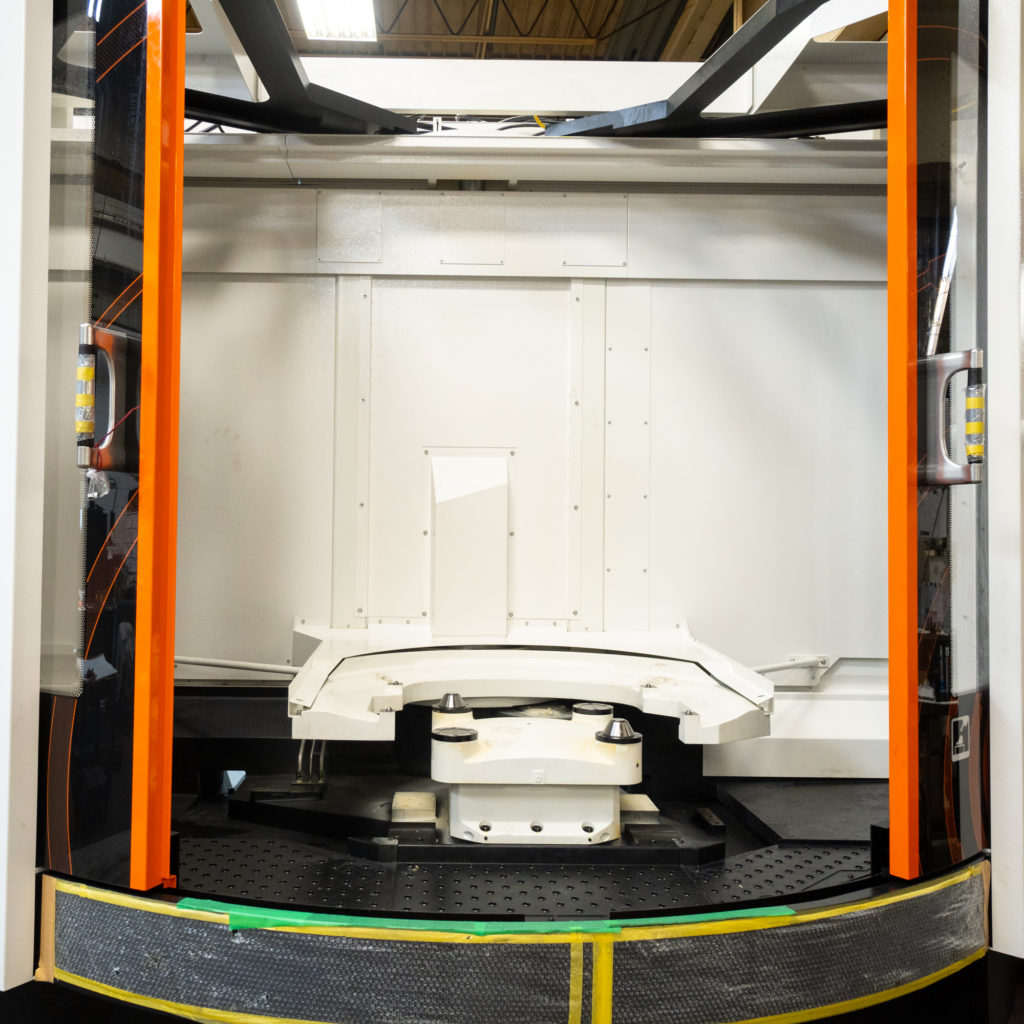

Kurt Machining is completing installation of our largest multi-tasking machining center to date from Mazak. The Vortex i-800V / 8 Multi-Tasking Machining Center expand our capabilities to machine parts up to 59″ in diameter, up to 63″ high and with a maximum weight of 6,614 lbs. This machine has 5-axis simultaneous machining capabilities allowing for parts to be completed in a single setup. This machine is perfect for complex large parts in the defense, aerospace and semiconductor industry.

This Mazak i-800V/8 includes a two pallet changer and provides unattended operation, allowing for off cycle part setup and reducing downtime.

Vortex i-800V / 8 Characteristics:

- Handles parts up to 59″ in diameter and 63″ high

- Spindle selection addresses various metal removal requirements

- Tool storage capacities from 43 to 160 tools offer high flexibility

- Two-pallet changer facilitates unattended machining

| Specification | Value | |

| Capacity | Maximum Workpiece Diameter | 59.060 in / 1500 mm |

| Maximum Workpiece Height | 59.060 in / 1500 mm | |

| Spindle | Spindle Taper | 50 |

| Maximum Speed | 10,000 RPM | |

| Magazine | Number of Tools | 43 |

| Rotary Axes | Spindle Tilt (B axis) | 150 Degrees |

| Table Indexing (C axis) | 360 Degrees | |

| Feed Axes | Travel (X Axis) | 66.93″ |

| Travel (Y Axis) | 59.06″ | |

| Travel (Z Axis) | 45.28″ |